Finned Copper Heat Exchangers

The finned copper coils that Cuproscambio produce range from 0.2 to 15 square meters and this wide range allows their use in various applications. Consequently this flexibility allows Cuproscambio to identify the best solution in terms of thermal conductivity, heat transfer surfaces and geometric shapes all of which meet the requirements of their customers. Cuproscambio is a company highly specialized in producing customized heat exchangers according to their clients’ needs.

Cuproscambio builds:

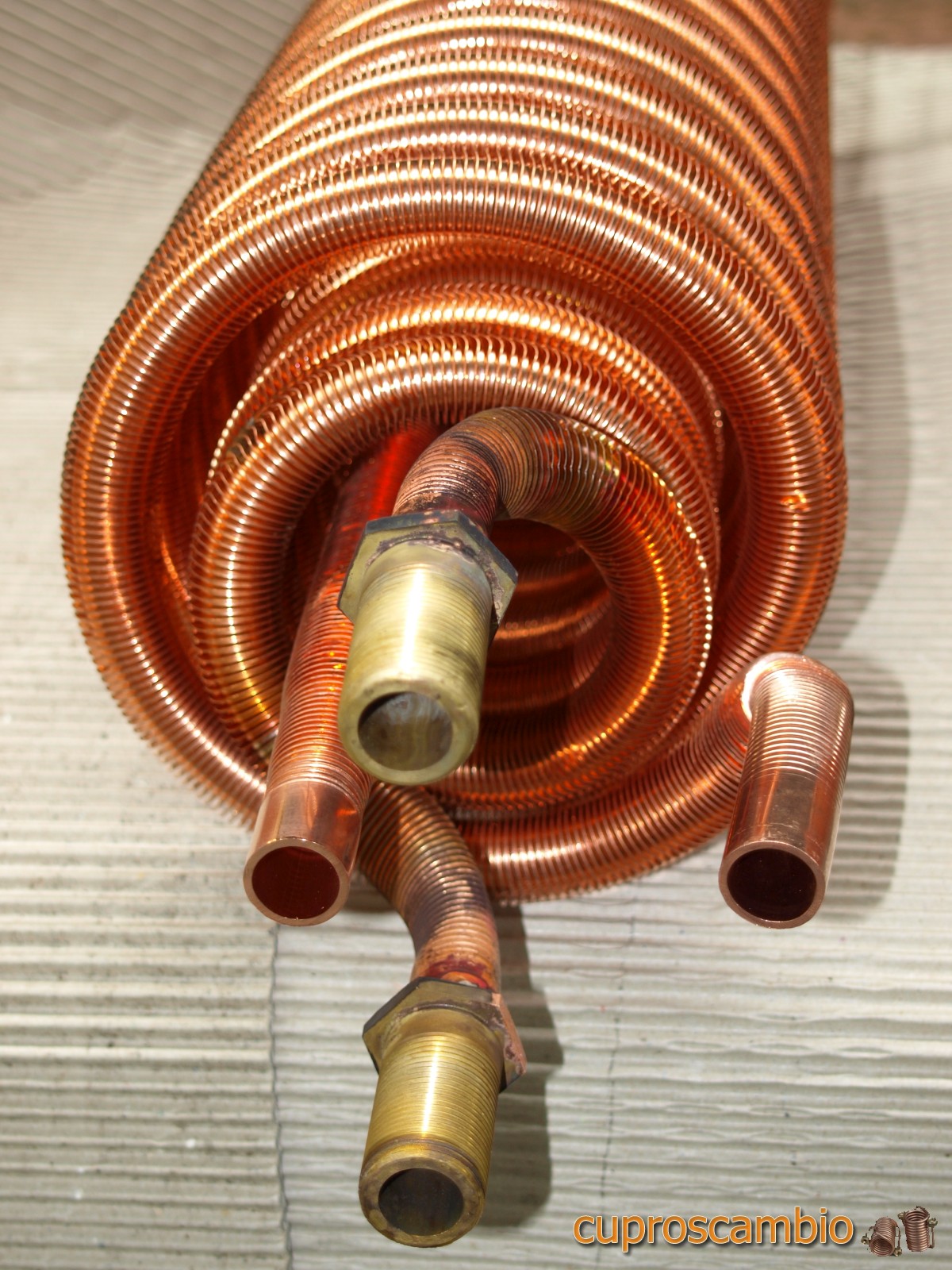

– Helicoidal finned copper coils: these have the “classic” coil form with diverse surfaces, and are used in many applications such as the protection against overheating (safety heat exchanger) in solid-fuel boilers, warming of drinking water, and heating water in kettles and puffers (hot water accumulators). These coils can be treated externally with nickel or tin.

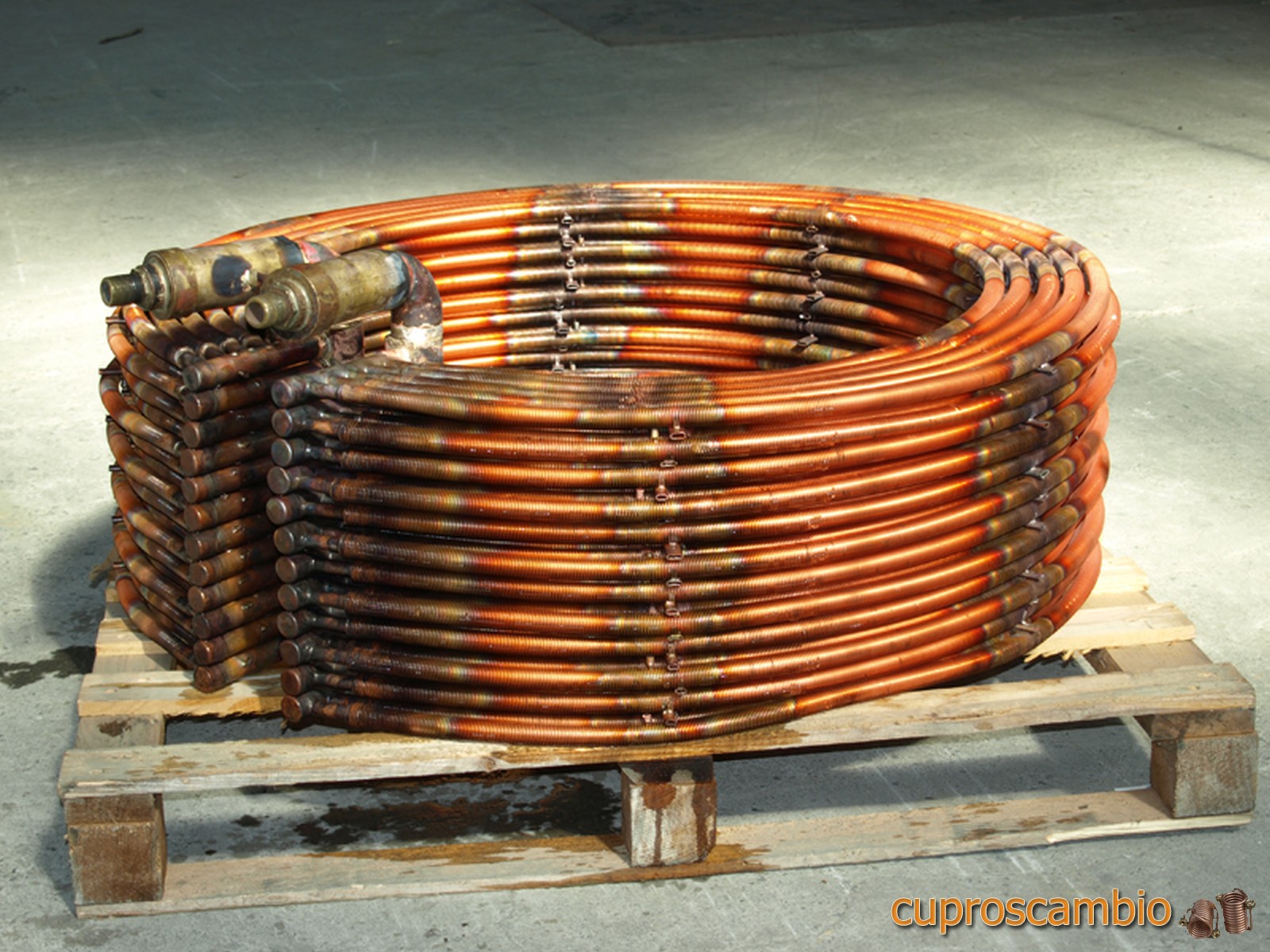

– Plain spiral finned copper heat exchangers: This type of heat exchanger is mainly used to exploit solar energy. It is also used to recover heat in pizza ovens.

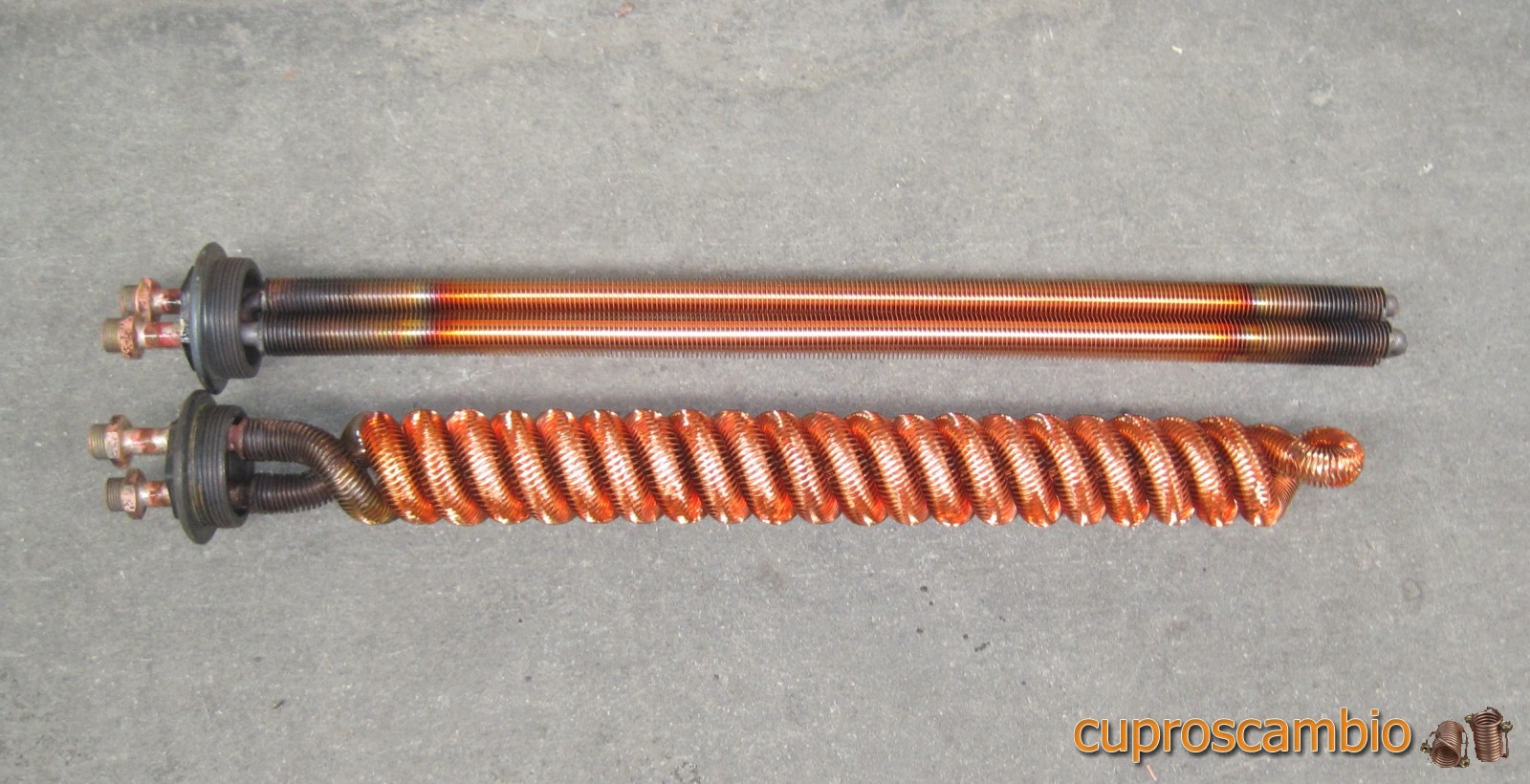

– Fork (wishbone shape) finned copper heat exchangers: This article is mainly used as a safety heat exchanger in solid-fuel boilers. Usually they have to be made to adapt to small and limited spaces and are made in many versions.

– Double layer (with single or multiple tubes) finned copper coils: this product is used to contain the overall dimensions or to increase the flow rate.